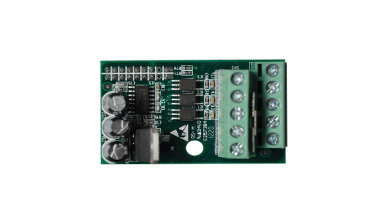

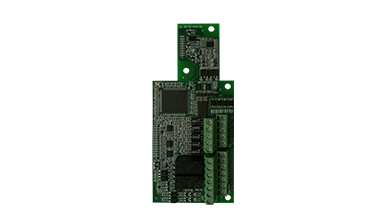

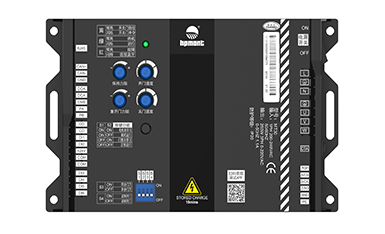

Frequency converter is an electric control equipment which applies frequency conversion technology and microelectronics technology to control AC motor by changing the operating power frequency of motor. Frequency converter mainly consists of rectification, filtering, inversion, brake unit, drive unit, detection unit microprocessing unit, etc. Frequency converter also has many protection functions, such as overcurrent, overvoltage, and overload protection and so on. With the continuous improvement of industrial automation, frequency converter has also been widely used.

Since the first frequency converter was manufactured in China, it has gone through 30 years of scientific research and development and application practice. With the improvement of electronic technology level and market demand, more and more types of frequency converters are available and their functions are becoming more and more perfect. Various frequency converter manufacturers have launched double competition in price and quality. In this competitive atmosphere, what development path will the frequency converter enter? What is the new situation for the development of the industry?

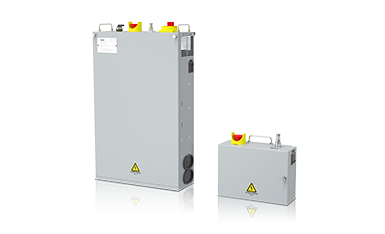

The common purpose of frequency converter is to adjust speed and reduce starting current so as to save energy. The demand for frequency converter varies with equipment operating voltage. Currently, there are three types of converters in the market: high, medium and low voltage. No matter which inverter is used, the manufacturers are all moving towards the same goal, i.e. high performance, multi-function and small size. This is also the demand of the users of the converter. Therefore, each manufacturer of the converter has put forward new requirements for its own development and production in the future.

Science and Technology Promote Performance Quality of Frequency Converter Products

For frequency converter, its performance is mainly depended on three aspects: the first is the influence of output AC voltage harmonic on motor, the second is the harmonic pollution and input power to power grid, and the third is the energy consumption of frequency converter itself. The basis of these points is that the frequency converter is required not only to achieve intelligence and integration modularity, but also to further reduce the loss caused by the use of the frequency converter and the switching process of the equipment. These aspects not only become the main manifestation point to judge whether the inverter is good or bad, but also the most important point for the inverter manufacturers to develop and improve continuously.

Nowadays, the functional requirements of products are getting higher and higher. A single application field cannot satisfy a wide range of users’ needs. Therefore, in order to meet the challenges brought by different application fields, frequency converters not only need to be updated continuously, but also need to maximize the diversification of products to meet the needs of different application fields. The applications of frequency converters now include a wide range of industrial production, urban water supply and power supply systems, and household electricity. In these areas, not only stable performance of frequency converter is required, but also products with full digital, systematic and network functions are required. The R&D and production of such products not only represent the progress of frequency conversion technology, but also bring more cheapness to production and life and drive further development of more industries.

Frequency converter industry has been developed and applied unprecedentedly in cement, elevator, printing, power and other modern fields as well as in medicine, communication, transportation, power, electronics, environmental protection, etc. Almost all industries of national economy are inseparable from frequency converter. As a whole, competition in China's inverter industry is becoming increasingly fierce.

Innovation of various information technology and fierce competition in the market have brought tremendous development power and space to the inverter industry. A new round of inverter innovation will become more and more intense and the inverter market will enter a high-speed growth period.

Article Source: China Power Electronics Industry Network