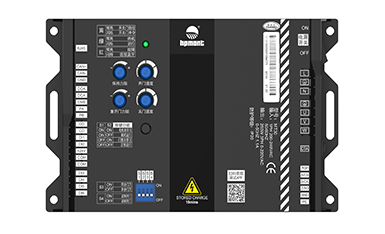

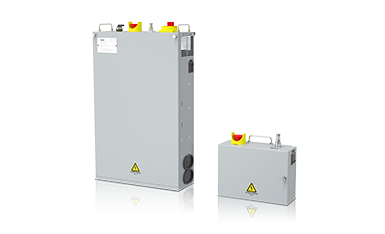

Frequency converter is an electric control equipment which uses frequency conversion technology and microelectronics technology to control AC motor by changing the frequency of motor working power. The inverter is mainly composed of rectifier (AC to DC), filtering, inverter (DC to AC), braking unit, driving unit, micro processing unit of detection unit, etc.

The inverter adjusts the voltage and frequency of the output power supply by the internal IGBT, and provides the power voltage required by the motor according to the actual needs of the motor, thus achieving the purpose of energy saving and speed regulation. In addition, the inverter has many protection functions, such as over-current, over voltage, overload protection, etc. With the continuous improvement of industrial automation, frequency converter has been widely used.

In recent years, the environmental remediation has been paid great attention to, which is enough to see the determination of the state to environmental governance, but also restricts the enterprises to pay attention to the expansion of economic development enterprises, and also to take energy conservation and emission reduction and low carbon environmental protection synchronization as the core value and premise of long-term development of enterprises. This is also the power source to ensure the sustainable and long-term development of frequency converter, PLC and electrical automation industry.

At present, the domestic inverter industry and the rapid economic development behind, the overall scale and strength of the domestic market electrical automation industry are uneven, many enterprises scale, capital strength, technical strength and industrial module are seriously backward than foreign brands, which has become the biggest obstacle to the sustained and high growth mode of the inverter industry in China.

With the increasing demand of large-scale frequency converter in China, the development of high-end frequency conversion products has been successful, and the intelligent development of frequency converter has become an urgent task. Our basic performance of frequency conversion has not reached the corresponding level, and the market has not developed to this extent. Fortunately, we have seen some domestic frequency conversion enterprises have carried out beneficial R & D practice, on the one hand, we have digested the advanced technology abroad, on the one hand, we tried to launch their own frequency conversion standards.

Therefore, it is very important to strengthen the construction of new industrialization. The so-called new industrialization is an industrialization process that does not sacrifice resources and environment. In order to achieve this in the process of promoting industry by inverter enterprises, it is necessary to rely on continuous technical input to lead the progress of science and technology, so as to maximize the utilization efficiency of resources and energy and reduce the consumption of resources;

At the same time, in the development trend of frequency converter, it is more intelligent, economical and environmental friendly, which has achieved the particle allocation of available resources, reduced unnecessary waste, implemented the green and low-carbon development strategy, and constrained all enterprises to reduce and reduce the emission of waste and pollutants in the process of industrialization, and build resource-saving and environmental friendly enterprises, This is what all inverter enterprises should do, and must.

Source: China Industry Research Network