Have you ever bought wooden desks, bookshelves, or other wooden furniture online?

Are you an assembling expert?

At the moment when e-commerce has penetrated into every aspect of our lives, purchasing furniture online is no more common.

In order to facilitate transportation, assembling furniture has become a trend so that we received pieces of assembled wood with different sizes, not the finished product.

Well let's see the woodworking machine !

Woodworking machine is mainly used for the opening, punching, slotting, milling and engraving of panel furniture. It is the necessary machine for wooden furniture.

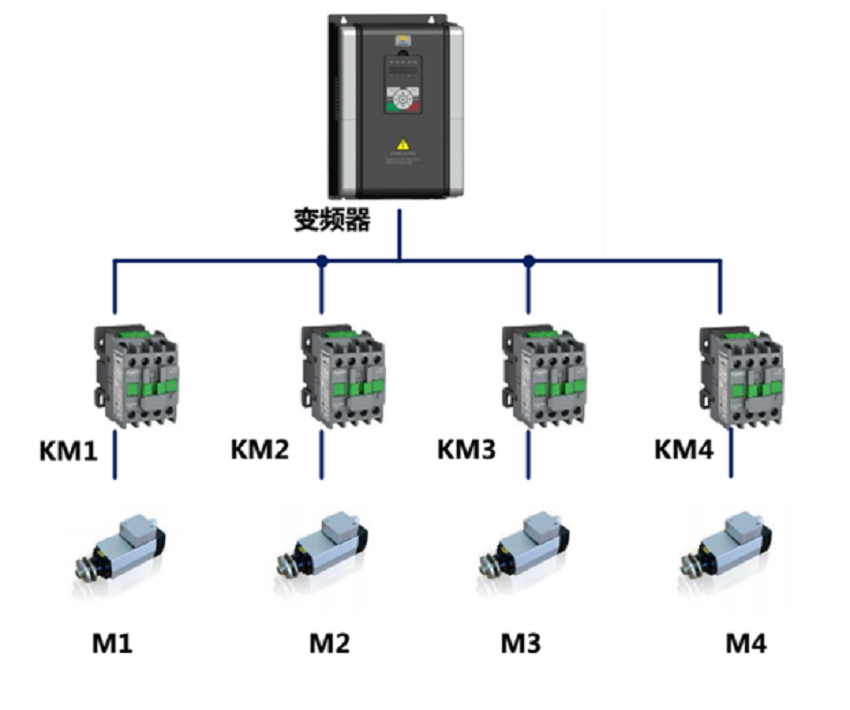

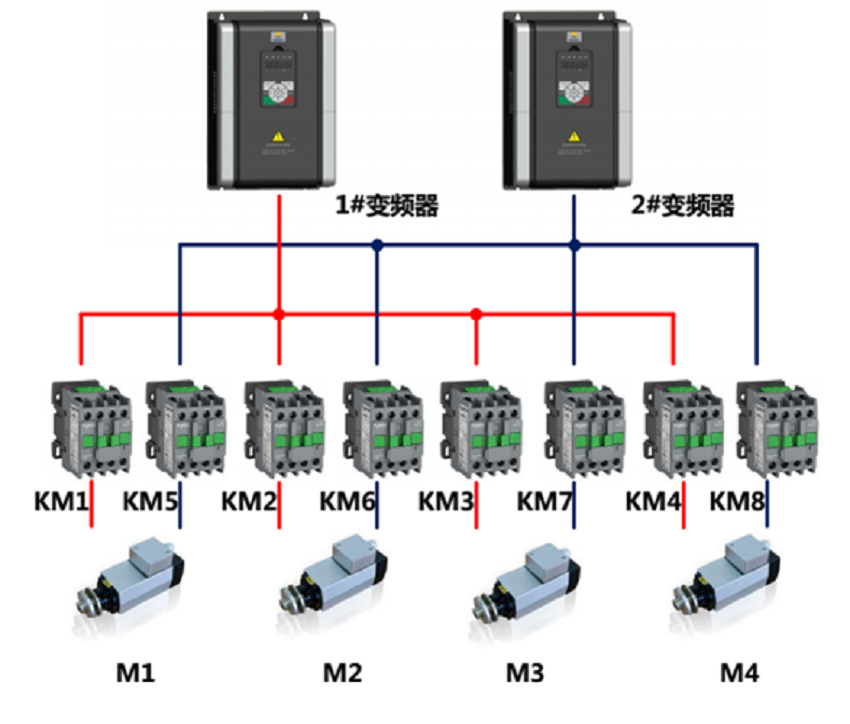

The control system generally drives the servo motor through the servo system to realize the positional movement of the space axis. The high-speed motor that realizes the process of punching, engraving, etc. controls the operation by the inverter. One motor completes a process, which means one machine completes it. The cutter needs to be equipped with multiple motors. Four motors are common to see .

So, is it necessary to configure one inverter for each motor?

Is there a control scheme that combines efficiency and cost?

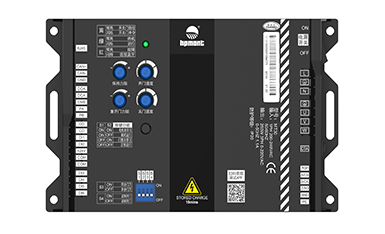

certainly yes, Hpmont woodworking machine-specific solutions features low cost, high energy efficiency give the answer you want.

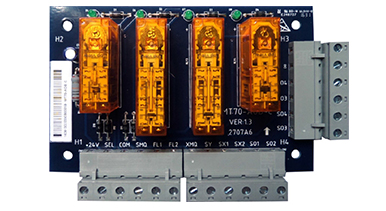

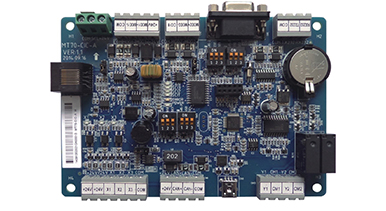

Solution 1: One to four

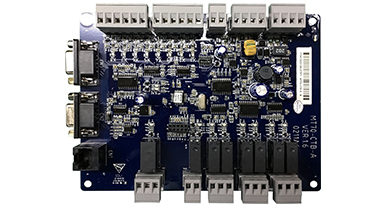

Solution 2: two to four

Feel the performance of the Hpmont special inverter

The Hpmont woodworking machine-specific solution incorporates industry-specific innovation algorithms and expertise, and works with precise logic control to achieve easy control and superior energy efficiency in process control, allowing customers to find more here. The answer to energy efficiency will also release more market vitality.