Hpmont has long been involved in this industrial chain to guarantee the production, transportation and processing of "weapons" and "grain and grass".

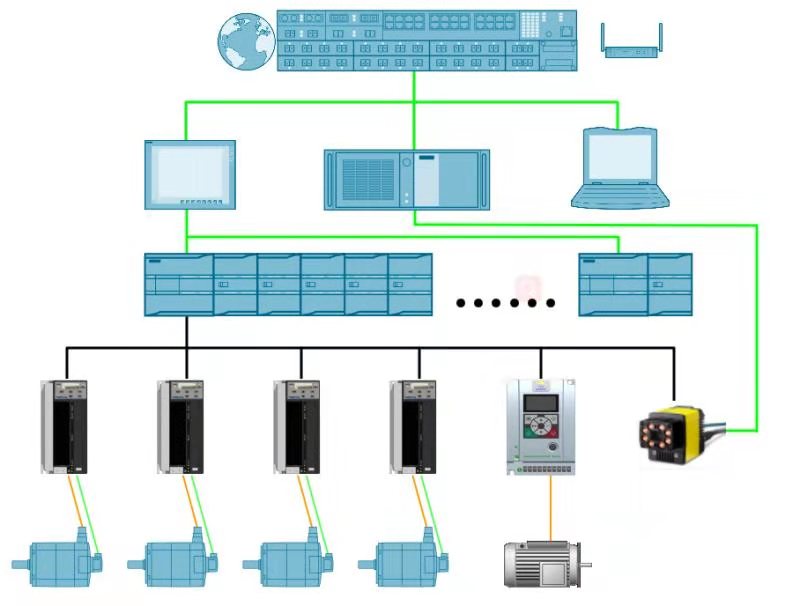

Although we are not a manufacturer of masks and protective clothing, nor a food processing factory, nor a logistics company, the electrical control solutions we provide are the core of the industrial chain and the "acceleration engine" to ensure all these operations.

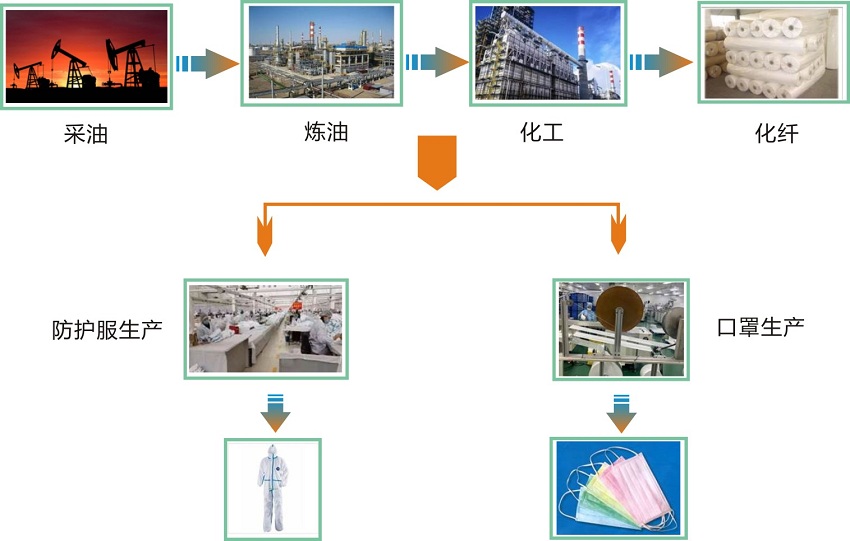

In the production line of masks, protective clothing and other prevention and control materials, Hpmont provides excellent and mature electrical integration solutions throughout a series of process flows from raw materials to finished products.

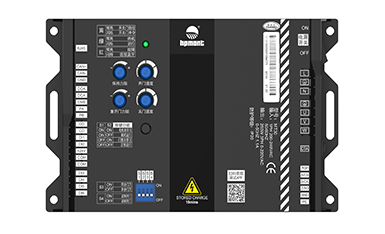

For example, the non-woven material of the mask comes from the oil separation. In the oil production process, Hpmont's HD50-Gseries linear motor driver can realize the upward and downward automatic circulation, and support the remote GPRS communication, which can bring significant energy saving effect;

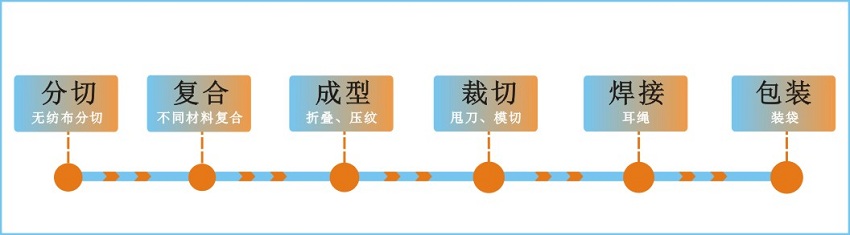

HD50 can flexibly adjust tension taper, select various torque control methods, and built-in automatic calculation module of coil diameter to realize automatic winding without stop in Nonwovens winding.

HS30 servo drive can achieve precise control in mask cutting and ear welding processes, which greatly enhance the safety, reliability and efficiency of the production line.

In the face of epidemics, time is money and efficiency is life.Faced with the huge throughput and complex logistics sorting system, Hpmont's HS30 servo driver and servo motor work closely together and can seamlessly connect with other logistics equipment, presenting faster sorting speed, higher accuracy and less labor than before.