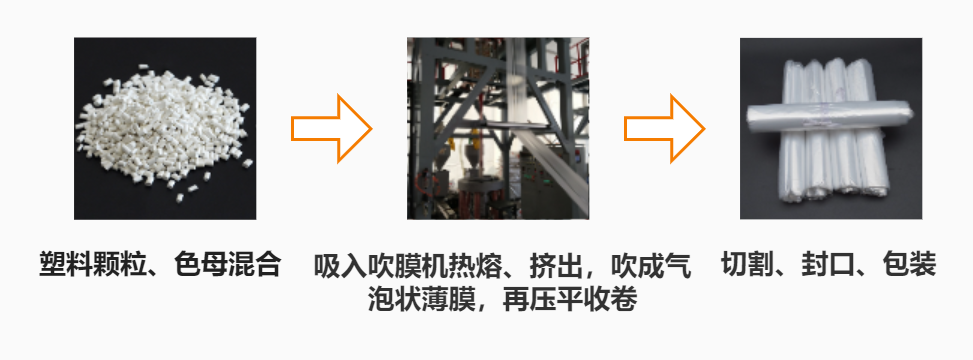

We have used so many colorful plastic bags with different shapes. They are within reach and everywhere,always ready to carry all kinds of things for you. But has anyone ever wondered how plastic bags came from?

If you search it in the internet , Google will tell you that plastic bags were blown out by Plastic Film Blower, and the quality of the final product depends on the process of blowing out. Being a professional within the field, I will say that it's totally true!

#General process of plastic bag production

Slide down to HD pictures and videos! ▲

In the process, film blowing is an important part of the production of plastic bags. If the speed of material extrusion and film traction is not synchronized during the period, it is very likely to lead to uneven film thickness, affect the quality of finished plastic bags, and finally cause a lot of waste of raw materials.

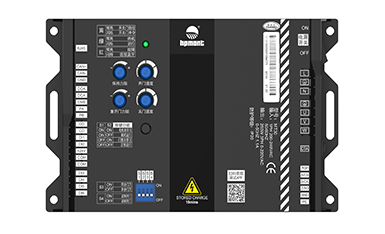

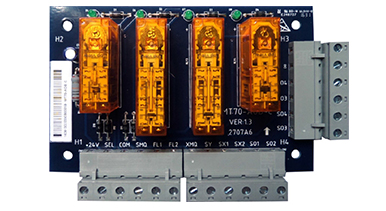

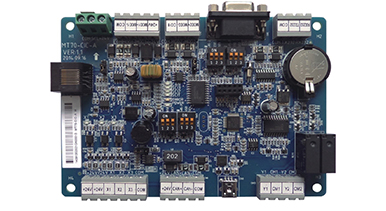

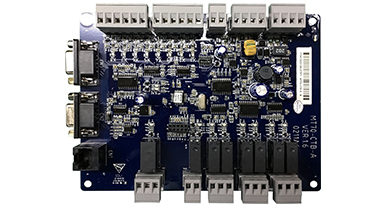

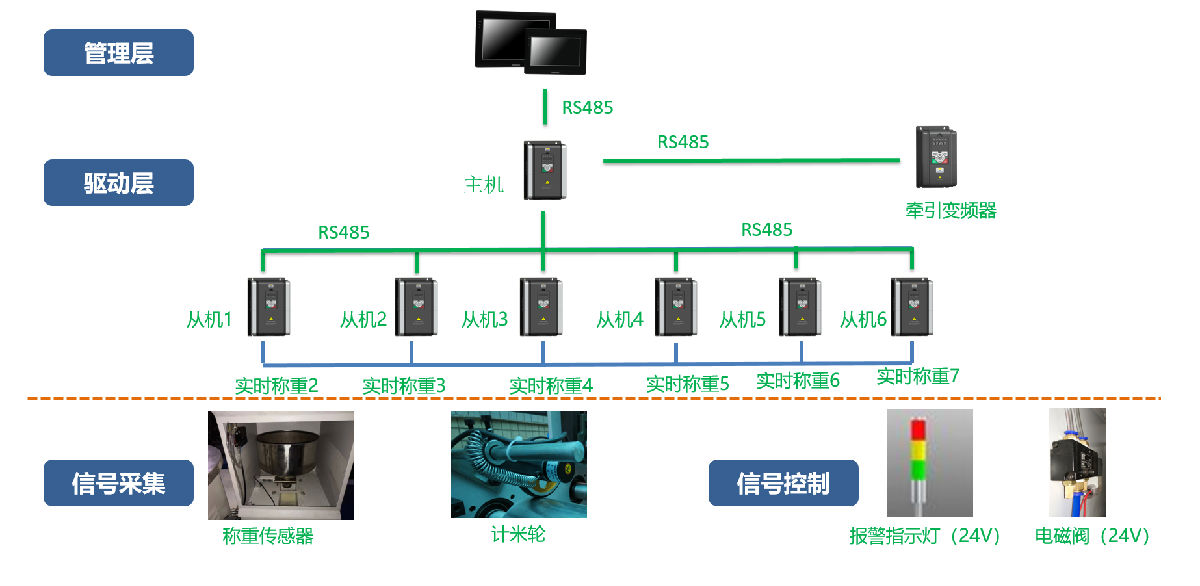

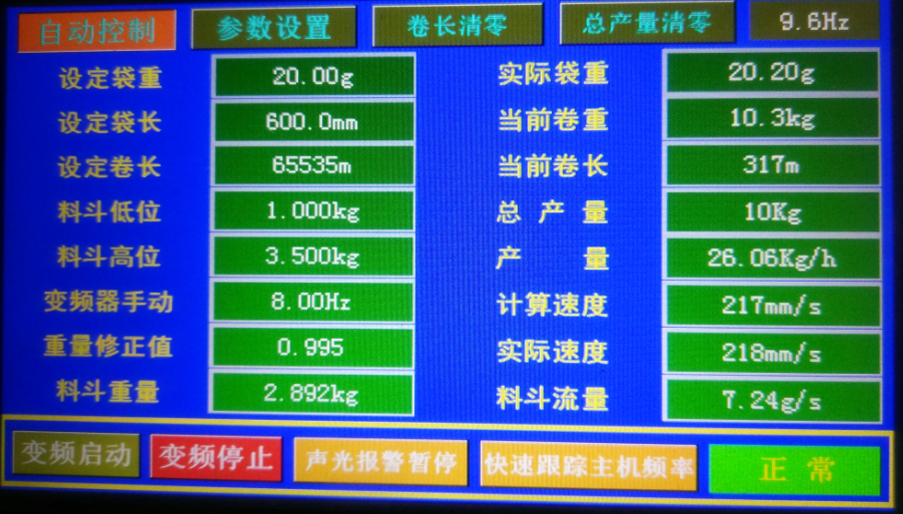

The control system scheme of Hpmont multi-layer coextrusion film blowing machine adopts Mick weight special frequency converter to monitor and feed back the production status in real time, and automatically adjust the traction speed according to the hopper margin to achieve uniform film bubble wall thickness. At the same time, it is equipped with IP65 high dust-proof design touch screen to provide convenient and efficient visual management and simpler operation.

Features

200-460v wide voltage design, specializing in all kinds of power grid instability.

Factory built-in macro parameters, simple debugging.

Independent cooling air duct design, equipped with high-speed DC fan, long-term operation is not afraid of "hot".

Multiple protection functions, instantaneous power failure without shutdown.

After strict EMC test, it meets IEC / 61800-3 international standard and is applicable worldwide!

Of course, the best place to test and evaluate the quality of products or solutions is the market. Outstanding products and solutions always have better sales and more applications.

1

Application of ABA coextrusion film blowing machine at an exhibition site in Dalian

2

Guangdong Jieyang, ABA co extrusion film blowing machine matching

3

Application of ABA coextrusion film blowing machine in a film blowing machine factory in Dongguan

4

Wenzhou, Zhejiang, application of single layer film blowing machine

5

Application of ABA coextrusion film blowing machine in Shantou, Guangdong

6

Transformation of single-layer film blowing machine in Zhuhai, Guangdong

The products and solutions of hipmount are really good. I'm not bragging. Otherwise, who dares to provide a 36 month warranty?