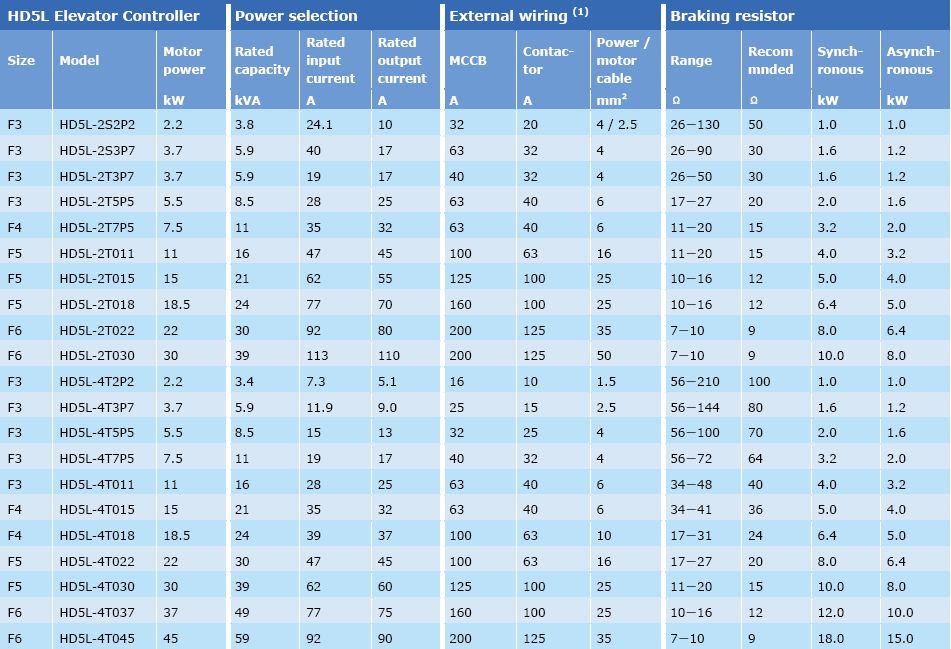

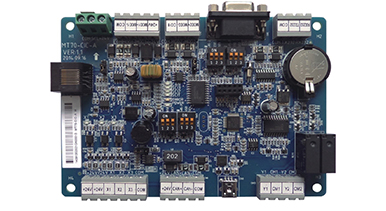

Synchronous and asynchronous motor integration

Support the controls of synchronous and asynchronous motor, and have good commonality.

With the leading vector control technology

Have the leading traction machine vector control technology and superior control performance.

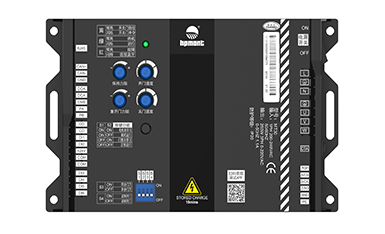

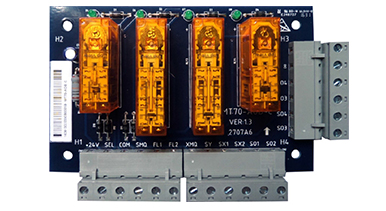

Multiple encoder interface boards

Can adapt to all kinds of encoders and have the FD( frequency demultiplication) output.

Smooth S-curve of acceleration and deceleration

The optimized S-curve of acceleration and deceleration can make passengers have a good sense of comfort.

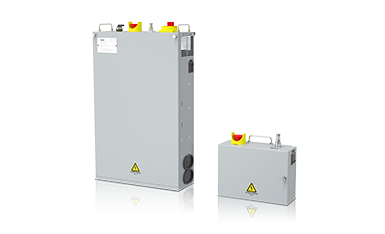

Four-quadrant operation

All are built-in the dynamic braking unit.

Can configure the power regenerative unit to achieve four-quadrant operation and energy saving.

Flexible start and stop time-sequence logic

Can match different elevator control and PLC.

Motor parameter static auto-tuning technology

When commissioning, no need for the car, you still can implement the parameter static auto-tuning for asynchronous motor and the magnetic angle static auto-tuning for synchronous motor.

Start torque auto-compensation for no weighing device

No need for the weighing device, you can achieve elevator start without impact.

Have good consistent, strong environ-mental adaptability, and more convenient for customer commission-ing, repair and maintenance.