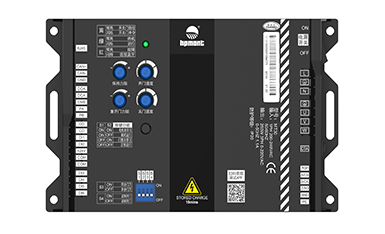

Since 2013, Hpmont inverters have been transformed and used in Cixi Chemical Fiber Industry of Ningbo. Because of the particularity of the industry, high reliability must be guaranteed to avoid huge production losses due to converter faults. Therefore, from the simplest fan to drum, packing, cleaning material to screw and draft gradually replace a Japanese brand inverter with monopoly position; It is concluded that the performance and reliability of the Hpmont inverter are no inferior to those of the imported one by the end users who have experience in field use.

Thus, a large number of loyal users represented by Dafa Chemical Fiber, a leading enterprise in the industry, emerged. Extensive use for retrofit and new line projects; At the same time, Hpmont, together with local system integrators, has implemented sub-station optimal control systems in the staple fiber industry, such as drum direct stop technology, pull-out electronic synchronization technology, screw constant pressure control technology, precision weighing system and other related semi-automatic control technologies. It has made the most positive contribution in improving process level and simplifying production cost.

At present, 8 projects of Hpmont are used in the new production line, and 300 units/year market are rebuilt. And for Japanese chemical fiber plant. Hpmont always adheres to the concept of "making excellent products wisely and moving customers", and works with partners to contribute to the rise of national industry.