Recently, the high-efficiency laminating machine developed by a company in Wuxi, Jiangsu Province was successfully applied to Dongguan Lee & Man Chemical Limited, and the inverters in the core control part of the laminating machine were all selected from Hpmont.

The new production line of Lee & Man Paper Mill is for the lamination of kraft paper, thereby reducing production costs and improving efficiency. Previously, the finished kraft paper was processed out for lamination.

The selection of inverters by Lee & Man Paper Mill has always been strict. All the inverters used before were imported brands. The successful application of Hpmont inverter in this company also proves the strength of Hpmont.

Application requirements:

Winding part (without tension feedback torque control)

Constant tension control, maintaining a constant tension throughout the winding process;

Fast torque response, timely response to acceleration and deceleration commands, and constant tension;

Good winding and forming effect

High-speed and non-stop automatic roll change

Unwinding section (with tension feedback speed control):

High-precision speed control, dynamically adjust the motor speed in real time, keep the tension constant throughout the unwinding process

Powerful PID function, stable tension pendulum throughout the winding process;

High-speed and non-stop automatic roll change

Application

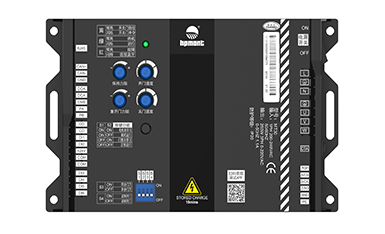

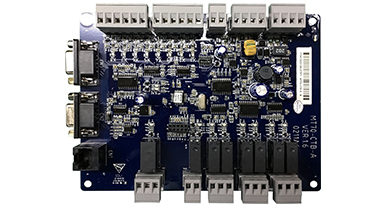

The seven inverters on the core of the laminating machine are all equipped with Hpmont inverters.

The host uses an 11kW HD30 inverter;

Rear traction uses a 7.5kW HD50 driver that achieves constant local tension for different materials;

The laminating part uses a 55kW HD30 inverter for the extruder section;

The winding section uses two 22kW HD50 drivers with tension-free feedback torque control;

The unwinding part uses two 22kW HD50 drivers with tension feedback speed control;

Winding and unwinding must realize high-speed and non-stop automatic roll change

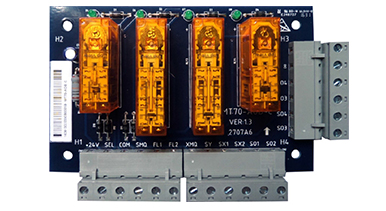

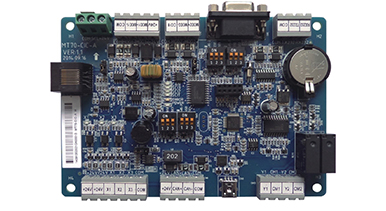

HD50 drive tension control features

The Hepmont HD50 high-performance vector control driver has built-in powerful tension control function. The good performance and the nuance of the tension control enable constant tension control in different applications, different materials and different control modes.

Main features

A variety of control modes, such as tension-free feedback torque control, tension feedback torque control, tension feedback speed control, constant linear velocity control, etc., can meet different needs of customers;

Built-in roll diameter calculation module, which can automatically calculate the current roll diameter;

High-precision PID control module for precise control of the tension pendulum;

Perfect pre-drive function, which can realize automatic roll change at high speed without stopping under various control modes;

A variety of multi-stage tension taper function, can achieve good winding forming effect after adjustment;

A variety of compensation methods to achieve smooth tension control under various conditions